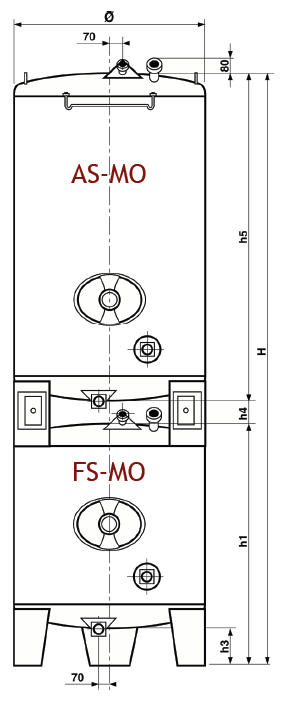

Description

If you don’t need to stack immediately: no problem! The base tank can be extended with a stacking tank also at a later date. Provided that the maximum total volume per stack is not exceeded, the two tanks can be combined without problems even when they are different sizes.

STANDARD ACCESORIES

- Tank shell and tank bottom made of AISI 304 stainless steel, surface IIId (2R), marbled outside

- Tank top made of AISI 316 stainless steel, surface IIId (2R), marbled outside

- From tank-ø of 1,000 mm upwards with lifting lugs

- Tanks from 2,000 mm tank height upwards and stacking tanks with ladder safety bow

- Vaulted, stable tank top with moulded-on forward up-slope for complete filling and ventilation assuring a very small air contact area

- Moulded connection neckwith filling and vent neck internal thread NW 50 Rd 78 x 1/6″

- Free-standing base tank on 3 welded-on legs

- Stacking tank with 3 welded-on stacking legs

SAMPLING

- Weld-on thread NW 10 DIN 11851 with sealing cap (for the installation of sampling tap)

MANHOLE

- Stable manhole neck seamlessly moulded from the tank shell

- Up to 320 litres capacity 320 x 250 mm

- From 525 litres capacity upwards 420 x 320 mm

- Door with butterfly bow and hand wheel

RACKING OUTLET

- Plain surface with drilled hole ø 48 mm (to hold flap valve Gr. 37 or weld-on thread NW 40, NW 50 DIN 11851)

- Up to 320 litres capacity fixed racking outlet plain surface

- From 525 litres capacity upwards with welded-on reinforcing plate

FILL LEVEL

- Weld-on thread NW 10 DIN 11851 with sealing cap including fastening points on tank shell (for installation of fill level indicator)

BOTTOM OUTLET

- Vaulted, stable tank bottom with integrally moulded forward down-slope for complete draining with moulded connection neck, impeding suction effect with bottom outlet neck

- Up to 820 mm ø NW 40 DIN

- From 1.000 mm ø NW 50 DIN