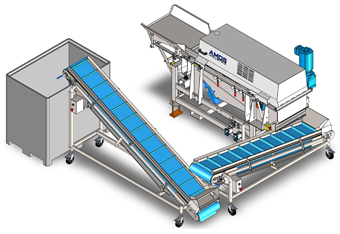

Amos Industrie unveils its latest innovation: Conv&Clean, a new-generation and hygienic conveyor belt. The fruit of a fruitful collaboration with Mix Buffet, a pioneering company in the delicatessen salad sector. Conv&Clean sets new standards in terms of hygiene, savings and resource reduction for the food industry.

A fruitful collaboration

The genesis of Conv&Clean relies on a close collaboration between Amos Industrie and Mix Buffet, a pioneer in salad catering.

Mix Buffet, was looking for an elevator that met the strict standards of the food industry in terms of hygiene and ease of maintenance. They chose Amos Industrie because of its expertise in manufacturing customized solutions made in France.

Innovation deployed and approved

The design of Conv&Clean followed a rigorous specification with a multi-phase development process, culminating in successful integration at Mix Buffet’s Guer factory in Brittany. Two units have already been ordered, demonstrating the efficiency and benefits of this hygienic solution.

SUPERIOR HYGIENIC FEATURES

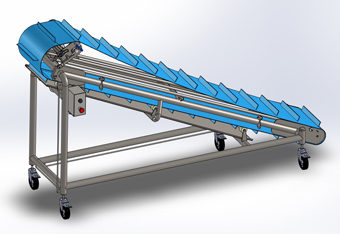

Conv&Clean stands out for its hygienic features, specifically designed for the food industry. Its round-tube frame reduces food product retention, making cleaning easier. Height-adjustable castors compensate for floor unevenness, ensuring a smooth flow of food products.

Design in 304 stainless steel, HDPE or PU ensures optimum reliability and hygiene. What’s more, the drum motor limits the risk of oil leaks, ensuring total protection against contamination.

Increased productivity

Conv&Clean is distinguished by its keyless design, enabling rapid removal of the belt, edges and hopper, simplifying cleaning operations. Its intuitive operation requires no training or tools for operators, contributing to increased productivity.

Meeting CSR challenges

Conv&Clean takes a responsible approach by offering reduced power consumption, contributing to substantial energy savings. Its convex shape also optimizes wash water consumption, underlining the company’s commitment to environmental sustainability.

Standards and certifications

Designed in compliance with the most stringent standards, Conv&Clean complies with NF EN 1672-2+A1 for hygiene, NF EN 418 for electrical safety, and NF EN 620+A1 concerning the safety of fixed belt conveyors for bulk products.

The design incorporates features that guarantee optimum hygiene, such as continuous welds, tightly sealed round tubes, and the use of food-compatible materials.

The Conv&Clean difference

- Ease of use

- Productivity gains

- Resource-saving

- High hygiene standards

Meet us at CFIA, stand 7-A38 to discover Conv&Clean!